ArboSkin: Durable and Recyclable Bioplastic Facade Mock-Up

ArboSkin: Durable and Recyclable Bioplastic Facade Mock-Up( Photo by Courtesy of Manfred Hammer & 3 images below)

The bioplastic facade mock-up was created within the framework of Research Project Bioplastic Facade, a project supported by EFRE (European Fund for Regional Development). It demonstrates one of the possible architectonic and constructional applications of the bioplastic materials developed in the course of this project. The blueprint is based on a triangular net made up of mesh elements of varying sizes.

Collaborating material scientists (Tecnaro), architects (ITKE), product designers (spek Design), manufacturing technicians (Bauer), and environmental experts (ISWA) were able to develop a new material for facade cladding which is thermoformable and made primarily (>90%) from renewable resources. ARBOBLEND®, a special type of bioplastic granules, can be extruded into sheets which are further processable as needed: They can be drilled, printed, laminated, laser cut, CNC-milled, or thermoformed to achieve different surface qualities and structures and various moulded components can be produced. The semi-finished products serve as cladding for flat or free-formed interior and exterior walls. The material can be recycled and meets the high durability and inflammability standards for building materials. The goal of the project was to develop a maximally sustainable yet durable building material while keeping petroleum-based components and additives to a minimum. The ecological audit was completed by project partner ISWA (Institute for water engineering, water quality, and waste management). Furthermore, the materials’s resistance to microbial degradation was determined.

This research project marks the first occasion for development of bioplastic sheets that are made primarily of renewable resources, can be freely formed, and are furthermore designed for application in the building sector and specifically for building exteriors. At the beginning of this project, such a product was not available on the market. The conception of this material as flame-retardant sheet material also aims at applications for building interiors With this new development, we can therefore soon offer a product that addresses two trends:

- the increasing demand for resource-efficient and sustainable building materials

- the increasing development of buildings featuring double-curved geometries and planar facade components with 3D effects (relief)

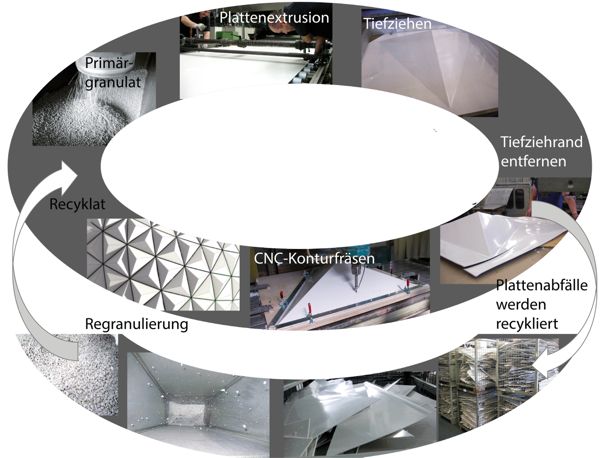

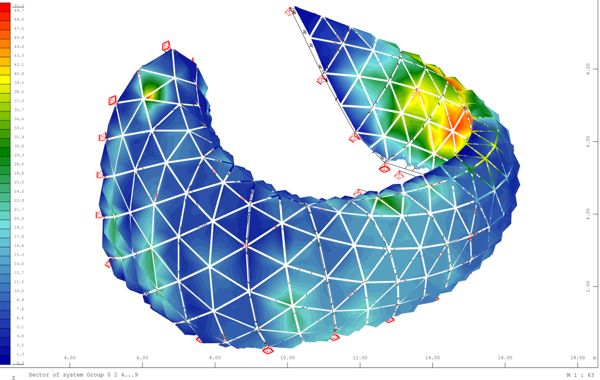

Extruded sheets made of the bioplastic materials are thermoformed into identical pyramidal moulding components. The necessary process of contour milling allows for multiple variations among the moulding components as identical thermoformed parts can be processed differently using various CNC milling paths. This allows for the cladding of freeform areas with a single moulded component. The plastic waste that results from CNC milling process is regranulated and directly returned to the extruding process. At the end of their useful life, the facade sheets can be composted or disposed of almost carbon-neutrally.

(image 2)

2 Concept sketch: Realization of freeform areas from identical thermoformed parts that are processed differently using various milling paths

(image 3 )

3 Schemata Production and Recycling

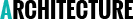

The freeform bioplastic facade functions as a sheet material based shell structure with additional loadbearing and bracing ring carriers and joists. Contrary to common non-loadbearing facade constructions, this construction involves the loadbearing properties of the double curved skin (made of 3,5 mm thick bioplastic pyramids that are mechnically coupled) in the loadbearing and bracing processes of the entire system. On the one hand, this innovative measure shows the potential of modified bioplastics as a bracing material (up to E≈4000N/mm²) suitable for exterior applications as it adds only a minor load due to its own weight (13kN/m³); on the other hand, it allows for the construction of a facade that utilizes a minimized number of points of support and/or mounting brackets on the structural work behind it.

(image 4 )

4 FE-Model Wind and snow loads

Mock-Up Data:

Location: Keplerstr. 11-17/ University City Center

Date of completion: October 2013

Area of facade: 145 m²

Material: biobased thermoplast (equipped with flame retardants) made from >90% renewable resources

Building: escape stairwell of lecture hall M17.02

Mock-Up Planning and Realisation:

ITKE (Institute of Building Structures and Structural Design) -Prof. Dr.-Ing. Jan Knippers,

University of Stuttgart, Germany; Faculty of Architecture and UrbanPlanning

Project Instructor

Dipl.-Ing. Carmen Köhler

Site Engineer

Dipl.-Ing. Manfred R. Hammer

Structural Engineer

Dipl.-Ing. Thiemo Fildhuth

Student Design Team :

Martin LouÄka, Peter Kohlhammer, Adrian Grygar

Programming of geometry

Martin LouÄka

Realization: A

drian Grygar, Serge Deisner, Maximilian Kurz, Martin LouÄka,

Paco Motzer, Jan Tondera, Dennis Gerlach, Alexander Mironov, Dominik Heizmann, Svenja Felis, Maximilian Schäfer, Benjamin Fritsch with support of Michael Tondera (Faculty workshop)

Facade Material:

Dr. Michael Schweizer, TECNARO GmbH, Ilsfeld-Auenstein

Production of the pyramids:

Frank Braun, Hans-Peter Braun, BAUER THERMOFORMING GmbH & Co. KG, Talheim

Product Design

spek Design

http://www.itke.uni-stuttgart.de/entwicklung.php?lang=en&id=58

The Architecture of Control

The Architecture of Control10 images shot by JEJ for FACADES

Joram Raaijmakers has studied the position of the watchtower within the military system. His aim was to trigger a conversation about the objects and to see where this can lead. He began by collecting different specimen, 'dismantling' them, and then manipulating their scale, material, and function. They ended up as a silver-plated teaspoon, referring to a traditional souvenir form. The coordinates of the original are stamped on the back, so people can actively seek them out using a GPS system, and discuss what they find with the people they meet there.

The Return of Cutty Sark

The Return of Cutty SarkCutty Sark London: The famous historic clipper is transformed into one of London’s most exciting venues.Â

"Seele’s newly-opened, state of the art glazed enclosure to the hull of Cutty Sark hosted a gathering for 350 guests from the Architectural Profession on July 11, 2012.The event was organized and hosted by seele, a world leading curtain wall manufacturer, who succeeded to provide an unforgettable evening within one of London’s most historic and scenic locations. The evening event was opened by two guest speakers, Richard Doughty, Chairman of the Cutty Sark Trust, and John Anderson, construction consultant to Cutty Sark Trust. The night then proceeded with an exquisite catering of food and drinks, live music, and tours of the upper deck and inner ship. Remarkably a museum space was transformed into a one of London’s most exciting venues. The experience of entering the glass enclosure and descending beneath the brass clad hull of the ship made it a fantastic space for a party. Once within, the mood was adorned by lighting which reflected against the brass hull creating a remarkable backdrop to the night". Nicolo Stassano

Images courtesy of Seele

“One great tourist attraction in London is the Cutty Sark sailing ship, now almost 150 years old. In its heyday one of the fastest clipper ships transporting wool and tea from the Far East to London, and since 1957 a museum ship, preserved in a special dry dock in Greenwich in south-east London. As the speed of Cutty Sark was due to the particular form of its hull, this is to be displayed in an optimum way upon completion of the latest conservation measures. To do this, the ship has been lifted by over 3 metres within its dry dock. This creates an accessible area beneath the hull that is enclosed in a curved glazed envelope. The ship rises out of this as though it was racing through the waves once again. The design for this and the levels beneath has been produced by London-based Grimshaw Architects.

The delicate glass design rises from the floor, sloping away from the ship at an angle of 9°, and then curves back abruptly towards the hull. The height of the façade varies from 1.90m above floor level in the middle of the ship to about 2.90m at bow and stern, necessitating a multi-curvature form. seele has been acting as a design consultant for this 90m long, 20m wide curving glass envelope almost from the very start. Based on experience gained at Westfield Shopping Centre, seele developed a free-form gridshell based on triangles with a side length of about 2m.

The loadbearing construction consists of steel hollow sections bolted together via six-way nodes. Concealed point fixings within the joints of the triangular insulating glass units fix the glass to its support. 2m wide trapezoidal elements and five-way nodes are used to provide a transparent façade. The entire construction is self-supporting. Elastomeric bearings support the inclined columns on their concrete plinths. The second support is a peripheral steel member supported on 24 columns anchored in the walls of the exhibition area – the columns that also support the Cutty Sark in its raised position. The design of the 1,500sqm area without any intervening columns is so delicate that the ship appears to be floating in a sea of glassâ€Â -seele http://www.seele.com